WELCOME TO SCHOCH TILE

TRANSFORM YOUR SPACE

WELCOME TO SCHOCH TILE

TRANSFORM YOUR SPACE

ABOUT US

Let's Make Your Vision A

Reality With Schoch Tile

Welcome to Schoch Tile, your premier destination for all things flooring and tile! We are a passionate team dedicated to transforming your living spaces with high-quality flooring solutions. Our mission is to provide a seamless shopping experience by offering a diverse selection of top-notch flooring products right at your fingertips.

Extensive Selection: A wide range of flooring types, colors, and patterns to suit any space

Quality Assurance: Products from top manufacturers that meet the highest quality standards.

Expert Guidance: Our team provides expert advice and personalized recommendations

Convenient Shopping: Shop easily from home with our user-friendly online store.

Customer Satisfaction: We deliver exceptional service to ensure your complete satisfaction.

TESTIMONIALS

What Our Clients Say

The flooring experience with your company is just what I've known it to be for some 30 plus years now. Complements to everyone who helped with our project. Jennifer who worked with insurance, paperwork, and quotes. PJ who helped us pick out vinyl flooring not once but twice and negotiated the best price Dennis who has worked with us in the past. Gary and Eddie, our newest acquaintances/installers who got in here and moved the project along quickly and professionally. Helped immensely with all the details. Especially communicating with us until everything was just perfect in our eyes.Going above and beyond with our needs. Great team, great company. Proud to be able to recommend your company to anyone with flooring needs.

Theresa Jung

Great work! Salesperson was helpful and not pushy. He worked on great recommendations based on budget and longevity. The installers were kind, respectful of the space and did an excellent job. Highly recommend!

Deidre Hazelbaker

You can sell a good product but if you don't have good installers the product is no good. The skill and expertise Gary and Eddie demonstrate along with their outstanding customer service, in a league of their own.

Joanie Meszaras

I called in needing some quick information. I highly recommend this company. It was refreshing to work with someone who cares about the customer and the work, not just about getting paid for a job.

Leah Webster

WHAT WE OFFER

Our Best Selling Products

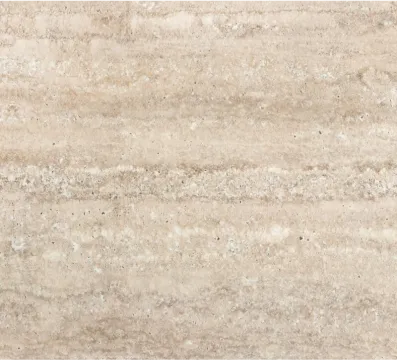

Leathered Granite

$65.00 $65.00

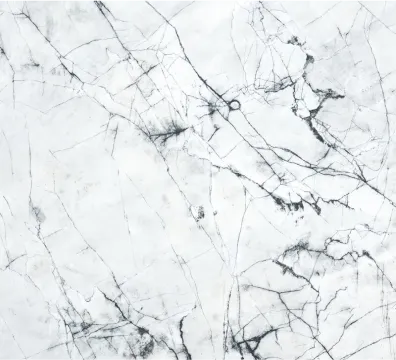

Calacatta

$20.00

Carrara white marble

$18.00 $20.00

POPULAR QUESTIONS

Frequently Asked Questions

What types of flooring and tile do you offer?

We provide a wide range of options, including ceramic, porcelain, natural stone, hardwood, laminate, vinyl, and luxury vinyl tile (LVT).

How long does the installation process take?

Installation timelines vary depending on the size and complexity of the project. Most installations take between 1-5 days. We'll provide an accurate estimate during your consultation.

How do I maintain and clean my new floors?

Each type of flooring has specific care requirements. We’ll provide detailed maintenance guidelines to keep your floors looking their best for years to come.

Do you offer free estimates or consultations?

Yes! We offer free in-home or on-site consultations and estimates to help you choose the best flooring for your needs.

Can you help with design and choosing the right materials?

Absolutely! Our team offers design assistance and guidance to ensure you select the perfect materials that fit your style and budget.

Schedule A Showroom Appointment

Simply Fill Out The Form, Come In, And Let Us Help With Your Vision

About Us

Transform Your Space with Top-Quality Craftsmanship

Contact Us

5282 Crookshank Rd, Cincinnati OH 45238

Phone (513) 922-3466

Copyright© 2026 Schoch Tile - All Rights Reserved.